Consumers are expecting on-demand convenience and personal touch from retailers and brands. The apparel retailers and brands in turn struggle to offer that, thanks to the limitations of an archaic, traditional supply chain.

A new cross-border trade tech startup is promising to make it simpler.

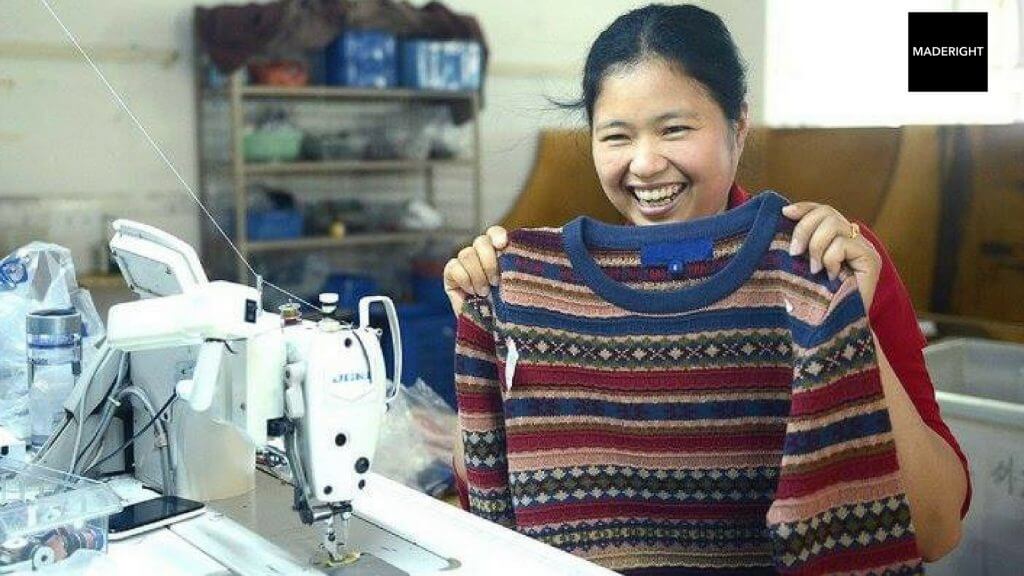

Photo Credit – MadeRight

The fashion retail market has witnessed several fascinating changes over the past few years. Clothing lines went global, trial rooms went virtual, and shopping went online. We now have websites, apps and online boutiques that help you pick, personalize and prance around in new clothes.

Behind the scenes, it’s a different story!

The way we make clothes hasn’t really changed in the last century. Of course, the machines are technologically advanced, the production lines are more efficient, and the labor is well trained. But how the business actually works, remains the same.

Kent Mori, Kevin Chan, and Shuo Yang experienced the frustrating world of manufacturing when they ventured into the world of fashion in 2013. They understood the traditional manufacturing is laden with loopholes and pitfalls. There was minimal technological advancement and businesses are still dependent on brokers and middlemen.

Most factories try to do business either in person or over the phone because there is no record of what is said and thus they are not accountable when things go wrong.

As Kevin Chan, the Co-founder of MadeRight says, “the manufacturing industry is as old-school as it gets. Most factories try to do business either in person or over the phone because there is no record of what is said and thus they are not accountable when things go wrong.”

The founders of MadeRight understood that these problems can be resolved by implementing smart technologies and processes in the system.

Other industries are already using automation, software, and tools in order to design sustainable supply chains. Then why should the apparel industry shy away from it?

The very question paved way for the formation of MadeRight. The web-based platform helps designers, owners, prototypers, and manufacturers work together. You can collaborate, interact and provide feedback in real-time. MadeRight can help you produce your own apparel line by providing a one-stop platform for services including designing, sourcing, sampling, and manufacturing.

Yarn rolls in a textile factory

Businesses are not happy with the traditional apparel manufacturing industry and rightly so. The industry is plagued by several issues!

Traditional manufacturing is a burden to small-scale businesses

The apparel industry is laden with contractors, subcontractors, questionable labor, and a large number of middlemen. It can be very intimidating for new ventures. Whether you are a startup, an individual designer, or a small boutique, choosing the right option from a plethora of factories and procedures can be daunting.

It is a logistical nightmare!

Getting clothes manufactured from other countries is a game of see-saw.

Designers and manufacturers ship prototypes back and forth for weeks. Design changes hinder faster production and there are constant shipment delays.

As a business, you are also forced to hire a different vendor for each part of the supply chain. You have a different vendor to buy inventory from, a different vendor to manufacture products, a different vendor to ship and so on.

With each of these vendors, you have huge amounts of files and operational details to take care of. Managing all these vendors and the associated logistics takes up a lot of time and manpower.

Watch how MadeRight solves the business woes by making apparel manufacturing more efficient:

Are the manufacturers ethical? There’s no way to know for sure.

In 2017, Nike faced protests organized by United Students Against Sweatshops (USAS). The protests raised allegations that the company is using sweatshops and child labor in its manufacturing units in Hansae and Vietnam. Not just Nike, several popular clothing brands like Zara, H&M, Forever 21 etc., have been accused of using sweatshop labor.

Since then, consumers have started supporting brands that provide environmental and social transparency. Brands are also making concerted efforts towards developing ethical supply chains. But the traditional manufacturing processes lack the transparency, making it difficult for you to ensure that the factories are treating their workers fairly.

Let’s not forget scammers!

The apparel industry has witnessed an exponential growth in online fraud attacks. You have fraudsters posing as middlemen, vendors, designers, and owners of manufacturing units etc.

Criminals have the ability to attack a business from various angles. In 2014 alone, retailers lost around $44 billion to fraud.

All these problems can weigh you and your business down. MadeRight provides a leverage! The company provides a single communication platform for designers, sample houses, and manufacturers to cut down the lead times.

If you love the craft and want to take your next idea to the market, MadeRight will help. Follow them on Facebook and Twitter for updates.

Subscribe to our newsletter