LA-based Relativity Space’s unique proposition of reducing the time taken to build and launch rockets has multiple investors fired up. In March, it closed a $35M Series B round led by Playground Global (which backs entrepreneurs working at the intersection of bits, atoms, and AI) to reach a valuation of $45.1M.

The startup’s valuation roughly amounts to the cost of launching one rocket but its solution will make the launch cheaper, quicker and more efficient. While companies like SpaceX and Blue Origin are investing in reusable rockets, Relativity is questioning why not 3D print all the parts and automate the whole process?

For Relativity Space, it IS Rocket Science

Ever since scientists like Stephen Hawking popularized looking up at the stars and not drawing a blank, government regulations and the cost of a rocket launch have been the single biggest barrier to reaching space. Relativity, like other aerospace manufacturers such as Rocket Lab, believes that the future of humanity is interplanetary and is trying to realize that belief by accelerating space exploration.

Founders Tim Ellis and Jordan Noone call Relativity a launch service provider. They started the company in late 2015 after raising a seed round from billionaire Mark Cuban. Ellis told CB Insights that they cold emailed Mark Cuban with the subject: “space is sexy – 3D printing an entire rocket”. After two months of due diligence, Cuban gave them $500K. The credit goes not just to a good email but pedigree – Noone worked at SpaceX while Ellis was an engineer at Blue Origin.

In fact, it was at Blue Origin that Ellis first toyed with the idea of 3D printing a rocket. However, it was evident that the Jeff Bezos company was focused on reusable rockets and not 3D printing. Ellis, on the contrary, believed that the future is 3D printing and that someone had to focus on printing, not just reusing, the entire launch vehicle.

3D Printing is becoming bigger

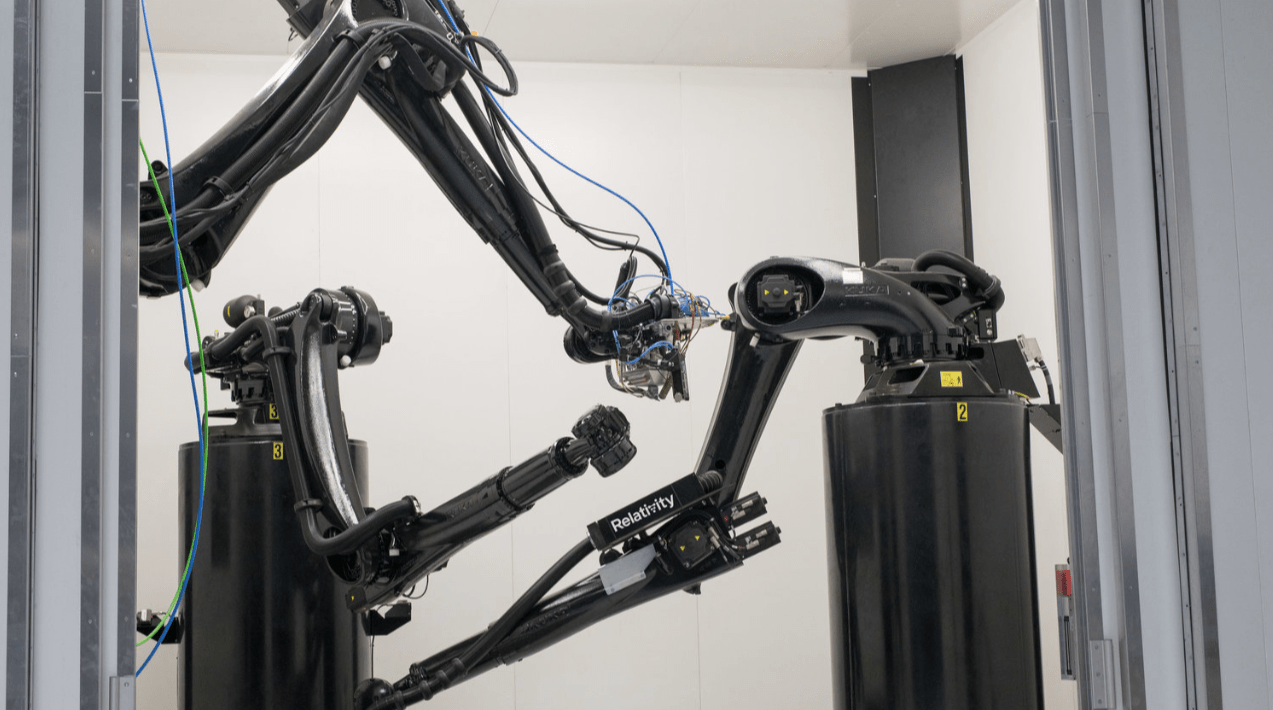

Since then, Relativity Space has built the world’s largest 3D metal printer called Stargate. Stargate uses sensors and function-based learning to print rockets made of stronger, reliable alloys. The startup, advantaged by this 3D printer, also has an in-house metallurgy and material characterization lab.

While the obvious advantage of 3D printing is lower costs in the long-term, there are other unseen advantages too. 3D printing ensures that building rockets now is much faster. Relativity claims that it takes them only 60 days to develop the whole rocket while it has traditionally taken companies 24-48 months. The LA-based startup is also entirely self-sufficient printing 95% parts of the rocket in-house. The other 5% being electric cables, chips, or rubber parts.

But one of the biggest advantages is Relativity’s intelligent processes and quality control. With 3D printing, the startup has brought in software-defined automation which can ensure smooth and quick changes to designs as compared to a factory with limited tools. This means that after 60 days, the rocket design can be altered and rocket designs, too, can rapidly evolve.

The startup’s fully 3D-printed engine called Aeon 1 uses liquid oxygen and methane as its propellant, which, Ellis believes simplifies their rocket design. The engine has been successfully test-fired over a 100 times.

Using Stargate and Aeon 1, the startup has built from scratch its first launch vehicle called Terrain 1. With a list price of $10 million, the startup is calling it the most cost-effective launchers in the world.

Living On Mars

Relativity’s cost effectiveness needs to be put in context: It is not competing with the likes of SpaceX or Blue Origin but is focused on sending smaller satellites in the low-earth orbit also called constellations. SpaceX and Relativity Space, therefore, with a per flight cost north of $60M to Relativity’s $10M, cater to different markets.

As each part is 3D printed, Relativity believes that even the initial cost of $10M will go down once the technology improves. The same cannot be said for traditionally built rockets which require a lot of human power and labour. “I don’t see a future in 20-30 years,” Ellis says, “where most of everything isn’t 3D printed”. 3D printing, then, aligns both economic and business incentives as it makes development light-weight, faster and ensures that the entire operation becomes cheaper – thus incentivizing more and more companies to adopt it.

Relativity Space’s Metal 3D printer Stargate which is also the world’s largest (PC: Relativity Space)

The future for Relativity, however, is more than just orbital satellites in the $350 M space industry. Ellis is keenly observing the rockets reaching Mars and wants to build the first 3D printed rocket to reach Mars. “If you’re going to build a city that’s self-sustaining,” Elis says, “Mars has the best conditions to do that”. Human life on Mars has been a persistent sell for Relativity and its a vision the company has full conviction in.

“In the early days of settlement, there will be few people living on Mars,” the startup’s website says. “Intelligent automation and lightweight, compact 3D printing are fundamental technologies needed to quickly build a new society with scarce resources – and the most scalable means to get back home”

The idea is mind-boggling and a giant leap from 3D printing jewellery or footwear. After being the first 3D printed rocket to Mars, Ellis and team want to be the ones to help create a self-sustaining city. After 3D printing rockets, 3D printing all kinds of other aircraft parts, cars or even houses, then, becomes a low-hanging fruit for the startup.

Till now, the startup paid NASA to test their rockets but now NASA has given them a free, too-good-to-deny deal. In March, Relativity signed a 20-year lease with the Stennis Space Center in Mississippi. This gives them access to an office building and four three-story tall engine test chambers made of blast-hardened concrete. Relativity, in turn, might give a free rocket to NASA. The preparations are ongoing as the startup is planning its first launch at the end of 2020.

“Like Google was the last search engine to enter the market,” Ellis says, “we also want to be the last in the market”.

Subscribe to our newsletter