Plus One Robotics, a San Antonio, Texas-based startup, is set to solve the labor shortage challenge facing warehouses and logistics companies, freeing up personnel for higher-value work. After having emerged from stealth mode in May this year, Plus One Robotics announced the launch of their first product for the order fulfillment and parcel shipping markets – the PickOne Perception System.

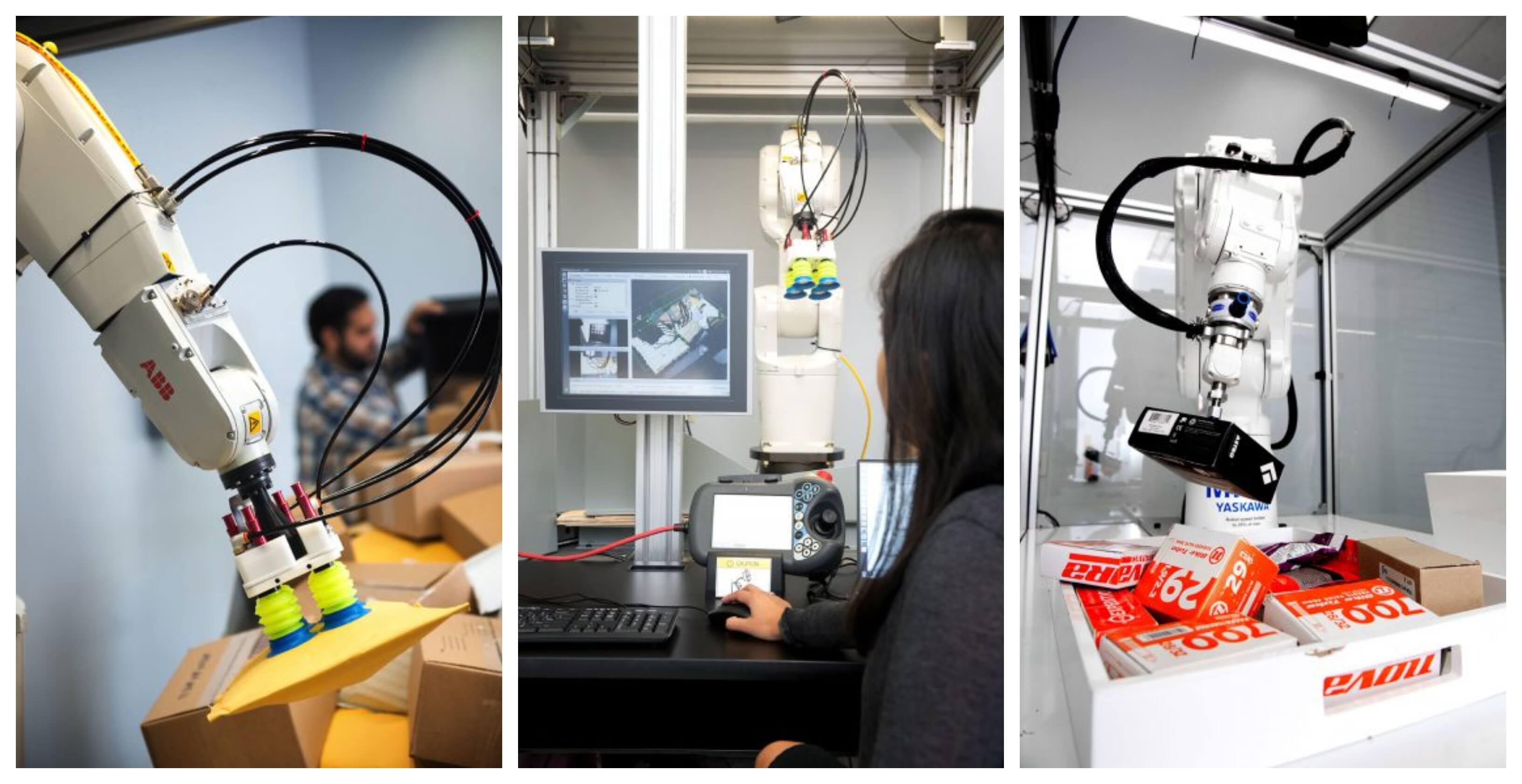

PickOne Perception System (Photo Credits: Plus One Robotics)

Labor Shortages and Customized Automation

With the rise in e-commerce, CBRE estimates that an additional 452,000 warehouse and distribution workers will be required just to fill the many warehouses that will emerge in 2018 and 2019. However, it has become increasingly hard to find and retain skilled talent and unemployment rates being the lowest in nearly 50 years isn’t making it any easier. Online retail orders require more logistic work per item than their brick and mortar counterpart. The processes in the space have many ‘touches’ along the supply chain. From the time an order is placed, till the item is delivered, the package is picked, sorted and placed numerous times. As the logistics industry is a ‘local’ sector which cannot be outsourced or shipped off to another country, an increase in the volume of packages moving over time would require the number of ‘touches’ in the process to increase. Shorter delivery times exacerbate these pressures. These labor-intensive processes throw up tremendous amounts of opportunity for automation.

While automation and robotics are the solutions to many of the challenges logistics companies face, the demands on these robots are very different from their industrial counterparts. These robots need to go beyond the repetitive and programmed movements in industrial settings to be able to spot, pick and move objects of varying dimensions and weights. Robot manufacturers have typically focused on the hardware with the software being brought in from open source projects. For complex logistics applications, robots need computer vision capabilities and AI enhancements. This is where Plus One Robotics’s PickOne Perception System comes in.

PickOne Perception System

The PickOne Perception System is an integrated software and hardware solution for sortation, induction, and singulation applications. Leveraging on advances in 2D and 3D image processing and machine learning, the PickOne Perception System images the input stream of packages in a fraction of seconds and generates pick position of a package for the robot. The robot arm with a vacuum gripper that is handling the sorting task then picks the parcel and places it in the desired location. If there are any errors while picking, the system commands the robot to reposition the parcel in a way so that it can be picked. If the accumulating spot is running low on parcels, the system sends out a signal requesting more parcels.

The advanced image processing and machine learning capabilities can pierce through a cluttered pile of mixed parcels of different forms and instruct the robot to pick packages from it even while the packages are jostling. The system can work at rates of 1500+ parcels an hour and with an accuracy of 98%+. Apart from being compatible with all major robot manufacturers such as Yaskawa, Denso, and ABB, the system can be retrofitted on to existing robots in the facility.

Plus One Robotics co-founders Erik Nieves (L), Paul Hvass (C) Shaun Edwards (R) (Photo Credits: Plus One Robotics)

A Decade In The Making

The founders began the journey of creating automation solutions for the logistics industry back in 2010. The evolution of the idea is also closely linked to various developments focusing on automation in logistics.

Back then, Erik Nieves (co-founder and CEO) was the Technology Director at Yaskawa Motoman Robotics, the 2nd largest industrial robot OEM. With a slowdown in the automotive industry, Yaskawa was evaluating developing automation solution for other industries. Erik was part of this initiative.

After evaluating various industries, they decided upon the logistics industry. The industry had very little automation as compared to industries such as automotives while having sufficiently large amounts of labor to merit automation.

In order to realize this objective and transition to robots that could perceive the environment, Yaskawa started interacting with various think tanks and research institutes. The research and collaboration that took place resulted in many groups and commercial ventures being created. It was during this phase that the future co-founders met.

In 2011, Yaskawa partnered with Willow Garage and Southwest Research Institute (SwRI). SwRI was to integrate Willow Garage’s Robot Operating System (ROS) into the Yaskawa’s industrial robots. Willow Garage’s ROS is an open source free to use initiative that was critical in propelling ROS developments. It was there that Shaun Edwards (co-founder and CTO) was a visiting researcher and was developing software for industrial robots. The following year, Shaun took his work forward and launched ROS-Industrial. Paul Hvass (co-founder and COO) who was at SwRI launched the ROS-I Consortium. These two groups continue to be the leading open source forces in industrial automation with support from giants like Boeing, ABB, Yaskawa, and Bosch.

There was another interesting event in 2012. Industrial Perception Inc (IPI), a Willow Garage spinoff, was launched focusing on developing 3D vision-guided robots for automated materials handling in the logistics space. This was the first commercial spinoff based on the idea that the industrial automation space needs to move towards logistics. A year and a half later in 2013, IPI was acquired by Google.

In 2015, Paul and Shaun developed the fundamentals of the PickOne Perception system. After spending 24 years at Yaskawa, Eric moved out to co-founded Plus One Robotics that year with Shaun joining in 2016. After helping launch the ROS-Industrial Asia-Pacific Consortium and making ROI-I global, Paul joined Plus One in 2017. One of the founders of IPI, Gary Bradski joined Plus One Robotics as an advisor in 2018. Many of the people that were key at driving automation in the logistics space during the nascent years are all back together at Plus One Robotics.

The Emerging Logistics Robotics Landscape

Historically, return on investment and costs were the biggest impediments all these years. However, the growth of scale driven by e-commerce growth and a drop in the prices of robots have made automation affordable. Logistics companies are spending big on upgrading and automating their warehouses. Earlier this month, DHL announced its plans to spend $300M on upgrading 350 of its 430 facilities in North America in order to keep up with the demands of its e-commerce business. Forecasts by ARK suggest a continued drop in robot prices. With buyers being price sensitive, this trend could help boost sales and automation penetration.

Investors are pouring in hundreds of millions of dollars into Robotics companies every month. Investments peaked at $2.1B in June this year. In response to growing demands on the logistics supply chains due to the rise of e-commerce, many robotics companies and service providers have been focusing on e-commerce applications. Warehousing has been a favorite with 4 major investments in November totalling $174.4M. The deal that signalled a shift in the space was Amazon’s acquisition of Kiva Systems in 2012.

In November, Plus One announced the close of its $8.3M in Series A funding round. The round was led by Pritzker Group Venture Capital with participation from Schematic Ventures, Zebra Technologies and several others. While Plus One Robotics has developed a system, others are focusing on developing integrated robots and have also raised millions in funding. Righthand Robotics, a pick and place robotic arm manufacturer, raised $23M in December. Soft Robotics has developed a robot called SuperPick specifically targeting e-commerce applications. In May, Soft Robotics raised $20M to expand operations.

As superintelligent AI is still decades away, Erik envisages a cognitive collaboration between humans and robots in the future where multiple robots could be handled by one person. While the robots have their tasks cut out, in the event they run into something they cannot cognize, human cognition and intervention will be required. Perhaps Plus One’s future products will be based along these lines and their motto – ‘Robots Work, People Rule’.

Subscribe to our newsletter