Sure, Burrow may have started off as an online-only ‘couch in a box’ business for superior quality sofas, but very soon it began making significant inroads into omnichannel retailing.

First, it crafted partnerships with popular retail stores (such as Bonobos), local coffee shops and co-working spaces that allowed people to try the Burrow couches in real life. When that proved to be a success, in August 2018, Burrow announced its decision to adopt the brick-and-click route with the opening of its first physical ‘experience’ retail store.

Based out of Soho, New York City, Burrow House (as the physical outlet is called) aims to give customers a carefully constructed product experience. In-store, shoppers are encouraged to lounge by the fireplace, get their very own home videos shot in a green screen studio, or just ‘movie and chill’ in a private screening room. Such a creatively-designed environment for product interaction is hoped to add customer loyalty and recall.

“Consumers don’t really want to just browse products. If they want to do that they can do it online,” said Burrow Co-CEO Stephen Kuhl, in a comment to Fox Business. “We wanted to create a space where people can organically try out our products.”

The Couch in a Box Business Saga

Headquartered in New-York, the direct-to-customer furniture brand is part of a sofa retail experience. What they offer is the option of purchasing a variety of easy-to-assemble, high-quality and customizable sofas, chairs, chaises and ottomans from the comfort of their homes. The highlight is that these sofas are delivered to the shopper’s doorstep in boxes via courier service. This would save a ton of the customer’s time and money that would have otherwise been invested in transporting the piece of furniture.

Reportedly, Wharton grads Stephen Kuhl and Kabeer Chopra started thinking ‘inside the box’, in 2015, while they were casually hanging out at a speakeasy. The grouse they had with the astronomical costs and inconvenience associated with buying a new sofa seemed to dominate their discussion. That is what marked the origin of an ‘aha’ moment.

While speaking of the sofa transportation and assembly challenges people face, Kuhl said to CNBC Make It. “There are so many companies that have improved the experience in buying products by selling them directly to customers online…Why can’t we do that with couches?”

A fair bit of research leg-work later, they realized that the gap in the market existed because of the high shipping cost. These rates were high owing to the bulky mass of regular sofas, which couldn’t fit into the UPS boxes or be stacked on top of each other. Also, ordinarily, the couch is shipped from the factory to the warehouse, then the retail store, before finally reaching the customer’s home. This made for a long and expensive supply chain.

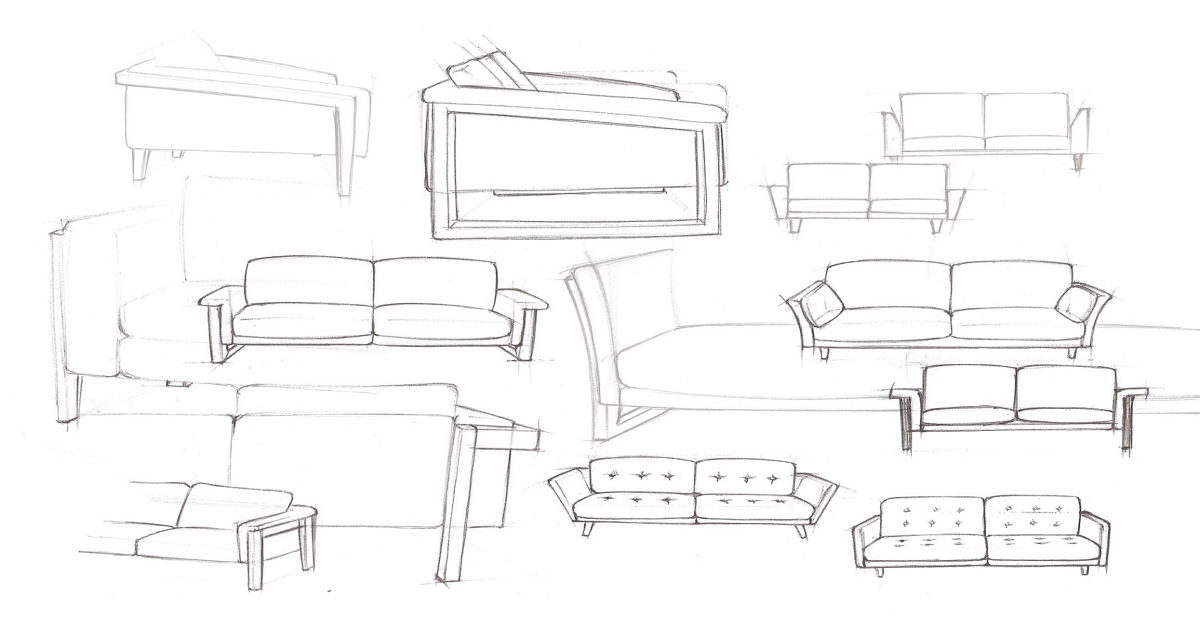

Enthused by the challenge at hand, the duo began to conceptualize a delivery-friendly sofa. They even hired a furniture designer and an engineering firm to create the prototypes.

Easy to assemble, compression sealed cushions, removable legs, and sturdy design with a foldable backrest: these were some of the design essentials that they wished to incorporate.

“We reverse-engineered a high-quality couch to ship in compact boxes that fit within the FedEx and UPS commercial weight guidelines,” Kuhl says.

The couch designed by Kuhl and Chopra could be shipped to any location in the US, directly from the factory, for less than $100.

They realized that a better product design and an online-only model meant a smarter logistics and supply chain. This would, in effect, remove all retail markups and save the end-customer over $600.

Operation Burrow is a Go!

For over two years, Burrow functioned as a bootstrapped startup. First, they collected close to $330,000 in funding from friends and family. They also zeroed-in on partners who were ‘flexible’ in terms of accepting payments and believed in the long-term vision of the company.

Then in April 2016, the duo attracted interest from Y Combinator, a startup accelerator. Burrow was accepted into the accelerator program and received cash influx to the tune of $120,000.

Yet by the time they were ready to start manufacturing the sofas, Kuhl and Chopra met with a fair amount of resistance from the U.S. manufacturers. The common reason for refusal was that the manufacturers couldn’t fathom why Burrow wants to use high-quality materials to build a seemingly ‘Ikea-like’ and ‘cheap’ self-assembly sofa.

Owing to the dismal response from the US, they decided to manufacture the first few prototypes at a factory in Mexico. With this setup, by August 2016, Burrow was open for preorders.

During this period, they faced quite a few supply and distribution delays that by November 2016 the team had to temporarily shut shop. They were unable to manage the volume of demand they were experiencing. Come January 2017, they were back on their feet (with improved capacities) and rearing to sell again.

Eventually, in January 2017, they were introduced to a Mississippi-based manufacturing facility, Chapter 3. Immediately seeing potential in the venture, the manufacturer agreed to take on the production of Burrow’s sofas. Finally, after much supply chain iterations and safety near-mishaps, Burrow officially launched in April 2017. Very soon, their sale figures were growing at 20% month on month.

Within less than a year of launch, in December 2017, Burrow raked up $3M in sales and closed $4.3M in seed funding. Then, in March 2018, Burrow received $14M in a Series A funding, led by American-based venture capital firm, New Enterprise Associates.

They’ve also recognised their target consumer base to be largely 20 to 30-year-old urban professionals. So, Burrow’s clever marketing campaigns, titled ‘good for nothing’, also panders to the needs of the millennial and gen-X populace of the nation.

Burrow offers Couches for Life

A U.S Census claims that the average American moves homes roughly 12 times in their lifetime. Burrow’s modular design with patent-pending latching system to secure the parts, makes its products perfect for renters. So, there is no need to buy new furniture with every move as the furniture can be split into smaller furniture pieces (loveseats and ottomans) to fit into any space.

What’s more, the sofas can be assembled in under 10 minutes and disassembled even faster into light parts that be easily transported. So, the couches don’t need a team to move it or even a carpenter to assemble it.

But the hero of this ‘couch in a box’ model is the fact that all of Burrow’s products are designed to come apart and fit neatly into standard-size shipping boxes. This helps save nearly 70% of shipping costs by making redundant, white-glove delivery charges.

A similar strategy is employed by mattress companies (such as Casper and Molecule) that ship their products at lower than traditional retail prices.

Burrow versus Competition

Competition in the ‘couch in a box’ space exists in the form of brands such as Article, Hem, Interior Define and Campaign. But Burrow stands out from the crowd for its aesthetics, USB cable integrated into the couch design, incredible ease of assembly, and a super-flexible return policy. All of their products come with a 30 day trial period and even the return shipping cost for the first purchase is borne by Burrow.

Burrow’s pricing is also on par with the rest. Its three seater sofas start at $1,095. A similar couch from Article would cost $699 and Interior Define would be priced at $2,000; while Campaign would cost $895 and Hem would be priced at $1,679.

Apart from the convenience of home delivery, people are ready to pay double of what Ikea charges for a ‘ couch-in-a-box ‘. This is because unlike Ikea’s particleboard-based designs, Burrow uses good quality, solid pinewood. Burrow’s couches are also super-customizable and locally sourced.

“We’re not copying Ikea. We’re going to use high-quality stuff and make a really nice brand and [provide] better customer service,” said Kuhl in an interview with Inc.

With the agenda of reducing the carbon footprint, all of Burrow’s sofas are made and sold in the USA. The couch in a box brand’s official page also claims that even the environmentally friendly raw materials for the sofa are sustainably sourced from the US and are free from harmful chemical treatments. Burrow even goes so far as to use packaging that is made from 100% recycled cardboard boxes, unlike the plastic used by most competitors.

Burrow, Grow and Branch-Out

According to Forrester, the US furniture market was worth $92Bn in 2017, of which only $7Bn of is purchases through e-commerce. This e-tail figure is expected to grow to $13Bn by 2022.

There’s a sizable opportunity here that brands like Burrow can tap into. Therefore, it is looking to hire aggressively, add new factories and non-sofa products. Kuhl was quoted in TechCrunch saying that they plan to grow Burrow into “an entire home lifestyle brand.”

“We want to be known for not making people compromise,” he continued. “Whether it’s price, quality, convenience, experience, comfort — any of those things, we want to provide the best overall experience.”

This sort of a superlative experience is exactly what Burrow seeks to deliver with their lively store in Soho. Such experiential stores could mark the revival of physical stores that have been relegated to the corner owing to the preference amongst customers to shop online.

Subscribe to our newsletter